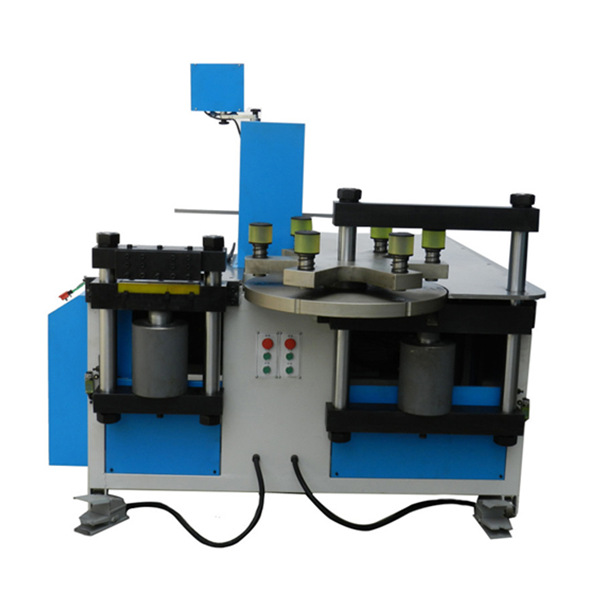

50 tons copper hydraulic busbar bending cutting and punching machine

Model: 503NCMXJ

Brand: Feiying

Oversize: 1800mm×1500mm×1300mm

Weight: 1800KG

Worktable size: 1400mm×1200mm

Second worktable size: 1000mm×500mm

1、 Introduction:

The machine has three working stations (units) for punching, cutting, and bending, which work simultaneously without interference. The punching station is of turret structure, the bending station is of a closed structure, and the bending angle is numerically controlled with memory function. The primary function is to process different specifications of copper and aluminum buses. When working, we only need to select the corresponding processing station; we can easily and quickly cut, punch (round hole, long round hole, square hole, special-shaped hole), fold flat bending, vertical bending, embossing, flattening, twisting and other different processing of copper and aluminum rows.

2、 Main features:

Panasonic PLC control, with an automatic stop function, and can control the cutting station and punching station downtime, compared with the traditional relay control, is more stable and reliable.

- The punching unit adopts the turret type four six or eight-die position integral turntable made of ductile iron material. The turntable is an integral processing part, and the numerical control machining center processes the die mounting hole. It has high precision, improves the die’s concentricity, prolongs the die’s service life, and does not need to replace the die frequently.

- The shear unit adopts the double column and double knife shear structure, and the upper knife and the lower knife are installed vertically and parallel to ensure that the shear opening is smooth, with no waste and no deformation after long-term use.

- The bending unit adopts closed bending, and a beam connects the force point and the force point with a thickness of 50 mm. The mechanical strength is greatly enhanced compared with the open bending.

- The bending angle can be numerically controlled. “Z-bend” can automatically calculate the required angle by inputting the vertical height (H) and bevel length (L) of the upper and lower planes. In the working process, it is convenient to process the workpiece by inputting the corresponding angle and the thickness of the bus bar, and it has the function of memory and error compensation.

- The working stroke of each processing unit can be easily adjusted so that the processing time can be reduced and the working efficiency can be improved.

- By changing the mold, it can also achieve a variety of processing functions, such as embossing, flattening, twist twist twist, and so on.

- The busbar bending machine has two operation modes: a manual button and a foot switch. The operation is simple, and the general skilled workers can use and operate it efficiently.

- The machine adopts Panasonic Siemens 30-point PLC control, which is more stable and reliable than the traditional relay control.

- The hydraulic oil tank is welded with a 3mm steel plate and phosphate, so the hydraulic oil will not deteriorate after long-term use.

- This machine adopts a one-to-one hydraulic supply mode, three oil cylinders, and three oil pumps, which do not affect each other.

- The hydraulic oil pipe adopts the national standard A-type connection mode, which is durable and convenient for maintenance.

- There will be casters on the machine, which can be moved easily.

- Many big customers use our busbar machines such as sate gird and sinotruk howo group and lots of electric company.

Parameter:

| Model | 503NCMXJ |

| Brand | Feiying |

| Oversize | 1800mm×1500mm×1300mm |

| weight | 1800KG |

| Worktable size | 1400mm×1200mm |

| Second worktable size | 1000mm×500mm |

| Maximum punching cutting and bending width | 260mm |

| Maximum punching cutting and bending thickness | 16mm(20mm is not suggest) |

| Punching hole scope | 4.3-32mm |

| Function: | Vertical bending, horizontal bending,punching,cutting,embossing and so on. |

| Motor:3x4KW yancheng lijia brand | Oil pumb:taiwan xinhong |

| Solenoid valve:Schneider – German brand | Relief valve:Schneider – German brand |

| electric relay:Schneider – German brand | Contactor:Schneider-German brand |

| PLC:Panasonic -Japan brand | Touchscreen:Pingtong – taiwan brand |

| Punching dies: | Φ7、Φ9、Φ11、Φ13、Φ17、Φ13×18、Φ21、Φ17×21 |

Shipping:

1. by express, such as DHL, TNT, UPS, FEDEX, EMS, and so on, Asia within 3 days, the middle east and South Africa within 5-7 working days, Oceania within 3-5 working days, south America about 7 working days. the advantage is door-to-door and high speed; it’s suitable for small and expensive spare parts.

2. by air, generally within 3-10 working days, it is suitable for minor and urgent purchases.

3. by land, suitable for border countries, such as Kazakhstan, Mongolia, Laos, Vietnam, Thailand, etc. Within 3-5 working days, we can send the goods to the border.

4. by sea, the most commonly used and most economical mode of transportation, it takes southeast Asia about 2 weeks, to Oceania about 3 weeks, the Middle East about 4 weeks, Africa about 30-50 days, south America about:30-45 days, it’s suitable for container and bulk cargo.