Copper Busbar Bending Machine

Discover the pinnacle of innovation with our CNC Copper Busbar Bending Machine, expertly crafted for B2B clients seeking a blend of advanced technology, portability, and manual hydraulic operation. Engineered for both on-site applications and workshop precision, this machine transcends traditional equipment boundaries, offering a comprehensive solution with state-of-the-art CNC technology for rapid and accurate bending. As a direct-from-factory supplier, we pride ourselves on delivering cost-efficient, high-quality, and robust machines, boasting superior production capacity. Ideal for upgrading existing setups or initiating new projects, our machines represent a smart investment for your business, backed by our commitment to top-tier service, dependable machinery, and market-competitive pricing.

Affordable Price

Customizable LOGO

Quality Inspection

We are a professional manufacturer

We can provide you with stock or customized copper busbar bending machines.

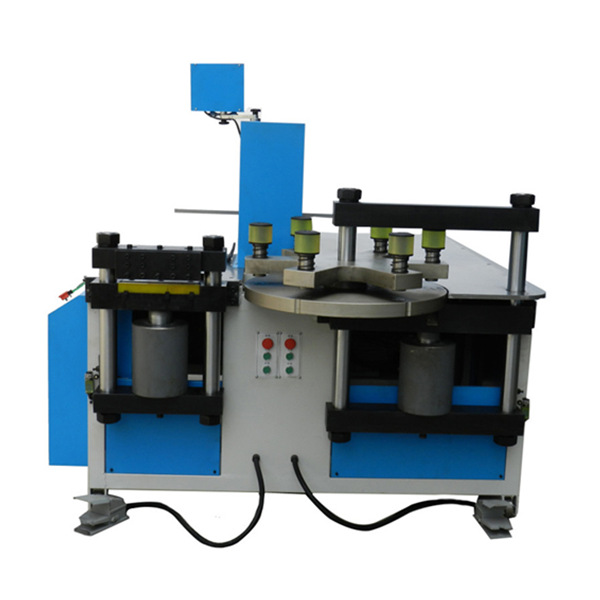

The 30-ton CNC (Computer Numerical Control) copper busbar bending machine is a cutting-edge solution tailored for precisely bending, cutting, and punching copper busbars.

Elevate your busbar processing with the 50 50-ton copper Hydraulic Busbar Bending Machine, a robust and precise solution designed for industrial excellence.

Designed for professionals who require precision, speed, and flexibility in their work, the DHY-200 combines the essential functions of punching, cutting, and bending in one compact device.

This versatile tool combines robust hydraulic power with precision engineering to accommodate a broad spectrum of bending requirements in the electrical, metalworking, and manufacturing industries.

This high-precision tool is designed to accommodate a wide array of bending tasks and is perfect for working with copper busbars and other metal materials, including brass and iron.

Why Choose Our Copper Busbar Bending Machines

Our Copper Busbar Bending Machines stand out in the market for several compelling reasons:

Advanced Technology: Incorporating the latest CNC technology, our machines offer unparalleled precision and efficiency in bending operations.

High-Quality Construction: Durably built, our machines are designed for longevity and consistent performance, reducing the need for frequent maintenance.

Versatility: Our machines are versatile enough to handle diverse bending tasks and are suitable for a wide range of applications, from electrical engineering to renewable energy projects.

User-Friendly Design: Easy to operate, our machines ensure a smooth and safe user experience, even for operators with minimal training.

Competitive Pricing: Despite the high quality and advanced features, our machines are offered competitively, providing excellent value for money.

Exceptional Customer Service: We provide comprehensive customer support, including training, maintenance services, and quick response to inquiries and issues.

By choosing our Copper Busbar Bending Machines, you’re not just buying a product but investing in a reliable, efficient, cost-effective solution for your bending needs.

Application Areas of Copper Busbar Bending Machine

Our Copper Busbar Bending Machine is versatile and essential in various sectors:

Electrical Engineering

- Power Distribution: Utilized in creating busbars for electrical switchgear, distribution boards, and substations.

- Control Panels: Fabrication of busbars for control panels in industrial machinery.

Manufacturing

- Heavy Machinery: Essential in the construction of electrical components for large machinery.

- Automotive Industry: Used in the manufacturing of electrical units for vehicles.

Construction

- Commercial Buildings: Installation of electrical systems in large buildings requires precision-bent busbars.

- Infrastructure Projects: Used in electrical installations for bridges, tunnels, and public utilities.

Renewable Energy

- Solar Power Plants: Crafting busbars for solar inverters and power distribution systems.

- Wind Energy: Wind turbines are used to create electrical system components.

Specialized Fields

- Marine Engineering: For electrical systems in ships and marine equipment.

- Aerospace Industry: In the manufacturing of electrical components for aircraft.

Our machine’s adaptability makes it a crucial tool in these varied applications, underscoring its indispensability in modern industry.

Need More Product Details?

We have further machines for you. If you can’t find the items you’re looking for above, fill out the form and tell us what you want.