Within the expansive machinery industry, there is a distinct piece of equipment that stands apart for its exceptional utility and efficiency: the busbar bending machine. This article aims to delve into a comprehensive understanding of its significance and explore its numerous benefits.

What is a Busbar Bending Machine?

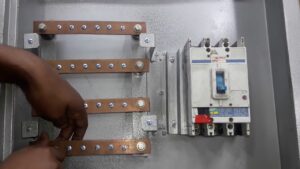

A busbar bending machine is a specialized tool to fabricate busbars, solid or hollow conductive bars used in electrical power distribution. These machines streamline bending, cutting, and punching busbars, ensuring they fit perfectly within electrical systems.

Why are Busbar Bending Machines Important?

Busbar bending machines ensure efficient and safe electrical power distribution systems. Providing precise bends and cuts ensures that busbars fit accurately, reducing the risk of electrical faults.

Overview of the Benefits of Using a Busbar Bending Machine

The advantages of employing a busbar bending machine in your operations are manifold, from enhancing accuracy to boosting profits. Let’s delve deeper into these benefits.

Benefits of Using a Busbar Bending Machine

Increased Accuracy and Precision

Busbar bending machines precisely bend busbars, ensuring they fit perfectly in electrical systems and minimize the risk of misalignment and electrical faults.

Improved Efficiency

These machines use automated features and advanced technology to produce busbars faster than manual methods, greatly accelerating production timelines.

Reduced Labor Costs

The busbar bending machine automates the process, reducing the need for manual labor and significantly saving labor costs.

Reduced Scrap

Achieving accurate bends and cuts the first time with precision reduces material wastage significantly.

Enhanced Safety

Automated machines offer safety features that protect operators, while manual bending can present safety risks.

Flexibility and Versatility

Modern busbar bending machines adapt to various sizes and materials, enhancing their versatility for diverse projects.

Durability

These robust machines are built to withstand the demands of industrial use, promising a long operational life.

Reduced Downtime

Features in these machines simplify maintenance and speed up troubleshooting, ensuring uninterrupted production.

Improved Product Quality

Precision tools produce high-quality end products that meet industry standards.

Increased Customer Satisfaction

Ensuring top-notch busbars improves product quality, enhancing business reputation and increasing customer satisfaction.

Boosted Profits

The combined benefits of reduced costs, improved efficiency, and enhanced product quality drive a major advantage: a profit boost.

Case Studies

ElectroFab Inc.

Before ElectroFab Inc. integrated a busbar bending machine, they dealt with high scrap rates and rising labor costs. After integration, they achieved a 50% decrease in scrap and a 30% increase in production efficiency.

PowerTech Solutions

After adopting busbar bending machines, PowerTech Solutions, a leading name in the electrical industry, experienced a 40% surge in customer satisfaction because of enhanced product quality.

Conclusion

The machinery industry boasts many innovations, yet the busbar bending machine shines with its unique benefits. It offers precision, efficiency, safety, and profitability. For businesses in the electrical sector, investing in a top-tier busbar bending machine isn’t just a recommendation; it’s a necessity.

Recommendations

When choosing a busbar bending machine:

- We should ensure it caters to the specific sizes and materials you work with.

- Prioritize safety features.

- Choose the machines that offer easy maintenance to reduce downtime.

FAQs

What materials can a busbar bending machine handle?

Most machines can handle a variety of materials, including copper, aluminum, and brass.

How does a busbar bending machine enhance safety?

These machines have safety features like emergency stop buttons and protective guards, reducing the risk of accidents.

Can these machines handle both solid and hollow busbars?

Modern busbar bending machines are versatile and can handle solid and hollow busbars.

How does the machine contribute to reduced labor costs?

Automation means the machine can perform tasks that would otherwise require multiple workers, leading to savings in labor costs.

Are busbar bending machines environmentally friendly?

These machines contribute to more sustainable and eco-friendly operations by reducing scrap and waste.

To sum up

Using a busbar bending machine offers clear benefits, including precision, efficiency, safety, and profitability, transforming the machinery industry landscape. Whether you run a small business or stand as a major industry figure, embracing this technology promises positive outcomes.