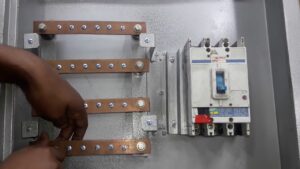

Busbar processing machines have revolutionized the power, electronics, and transportation sectors. These machines make manufacturing different specifications and shapes of power busbars possible, efficient, and precise. This article peels back the layers on the advantages of busbar processing machines, providing an in-depth understanding of their role in modern industrial processes.

Efficiency and Precision in Production

One of the prominent advantages of busbar machines is their capacity for efficient production. With the capability to complete multiple processes in one go, these machines greatly enhance production efficiency. Moreover, they ensure the quality and accuracy of the busbar, eliminating defects and inconsistencies.

Busbar machines can handle different busbars — from right-angled ones to curved variations. These machines can customize busbars with cutting tools and molds to specific shapes and specifications.

Embracing Automation

In an era defined by automation, busbar machines are not lagging. The automated operation of these machines reduces production costs and manual error rates significantly. The machine completes every marking, cutting, and molding action automatically. This feature reduces worker fatigue and burden and improves overall work efficiency.

The high level of precision achieved by these machines deserves mention. With CNC technology, busbar machines can cut and process busbars with up to 0.1mm accuracy.

The Special Features of Busbar Processing Machines

Busbar processing machines are particular types of CNC processing equipment primarily used to create slotted edge sheaths for busbars and conductors.

Precise Processing

These machines take precision to a new level, processing busbars with millimeter-level accuracy. This ensures that the busbar specifications fully meet the requirements.

Versatility

Busbar processing machines can handle various shapes of busbars, catering to a wide range of market requirements.

Automation and Safety

These machines’ fully automatic mode of operation enhances work efficiency and production capacity. Additionally, these machines ensure high safety during operation, eliminating risks of worker collision or misoperation.

Labor Cost Saving

Busbar processing machines reduce working hours and workers’ fatigue, saving labor costs and enhancing production efficiency and quality.

User-Friendly Interface

Designers have equipped busbar processing machines with an intuitive and straightforward interface, simplifying the machine’s use and maintenance for operators without requiring extensive technical support.

Conclusion

Wrapping things up, we can’t ignore the pivotal role that busbar processing and busbar machines play in the industry. They’re the wizards behind the curtain, deftly shaping the future of power conversion, wiring, and maintenance work with precision, efficiency, and versatility. These machines show how technological leaps can fuel industry growth and spark innovation.

FAQs

What are Busbar Processing Machines?

Busbar processing machines, specific types of CNC processing equipment, primarily create slotted edge sheaths for busbars and conductors.

How do Busbar Processing Machines Improve Efficiency?

These machines improve efficiency by automating multiple processes, reducing production time and manual error rates.

Can Busbar Processing Machines Handle Different Shapes?

Yes, busbar processing machines are versatile enough to handle different shapes of busbars, including right-angled and curved ones.

Is it Safe to Operate Busbar Processing Machines?

Yes, these machines are designed with safety features that eliminate risks of worker collision or misoperation.

Do Busbar Processing Machines Require Technical Support?

While some technical knowledge is beneficial, these machines are designed with a user-friendly interface that makes operation and maintenance easy.