A busbar machine is a specialized device used to cut, bend, punch holes, and process copper or aluminum busbars for electrical power distribution systems. Busbars conduct high electrical currents between components in switchgears, transformers, motors, and power grids.

Understanding how busbar machines work provides insight into an essential (yet often overlooked) aspect of power infrastructure. As a professional busbar machine manufacturer, I am writing this guide to cover everything you need to know, from busbar machine functions and capabilities to models, applications, and more.

An Introduction to Busbars

Before diving into busbar machines, let’s cover what busbars are and why they matter.

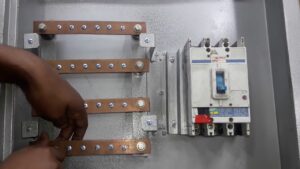

Busbars are strips or bars made of highly conductive metal, usually copper or aluminum. They transport electricity at high currents from one section of a power system to another.

For example, a generator produces electricity that gets carried by busbars to transformers and switchgears then distributed across power lines. Without busbars, transmitted electricity would overload standard wires and connections.

Busbars come in different sizes and capacities but always need custom holes, bends, cuts, embossing, and other modifications to work for specific applications. And that’s where busbar processing machines come into play.

What Is a Busbar Machine?

A busbar machine (also called a busbar processing machine or busbar fabrication machine) is an industrial device designed specifically for cutting, punching, bending, and otherwise processing busbars. These rugged metalworking machines utilize hydraulic, pneumatic, or servo-electric power to drive specialized tooling that alters the shape of busbars through pressure and machining.

The various capabilities of busbar machines enable the cost-efficient, high-volume production of busbars ready for installation into electrical switchgear, transformers, control panels, and other heavy-duty equipment.

Key Functions and Processes

Modern busbar processing machines offer an array of fabrication capabilities to handle nearly any busbar modification required, including:

Cutting

Precisely cutting busbars to length is essential for creating busbars ready for installation. Busbar cutting machines utilize industrial shears, saws, lasers, waterjets, or machining tools to slice busbars.

Cutting permits the creation of custom busbar lengths to suit specific applications. It also enables mass production of uniform busbar lengths.

Punching

Punching machines use hardened guides and pneumatic, hydraulic, or servo-powered punching units to create holes, slots, and other voids in busbars.

The punching process facilitates electrical connections, ventilation, mounting points, and compatibility with various busbar accessories. Customized punching tools create holes for bolts, wiring, sensors, and more.

Bending

Bending busbars allows them to fit into tight electrical enclosures and route through equipment. Busbar benders use precision-ground dies and hydraulic/servo-powered presses to form precise U, Z, L, and custom bends.

Bending also permits busbars to avoid obstructions and connect varying equipment efficiently within confined spaces.

Embossing

Embossing machines imprint identification information, branding logos, part numbers, and electrical ratings into the surface of busbars. Embossing helps ensure proper identification and tracking.

Other processes

In addition to the main functions above, busbar machines offer several other fabrication processes, including:

- Stripping insulation

- Flattening

- Deburring sheared edges

- Label/marker printing

- Twisting busbars

- Butt welding

- And more…

The wide range of busbar machining capabilities enables the production of finished busbars ready for installation into electrical power systems.

Busbar Machine Models and Configurations

There are several common classifications and configurations of busbar machines available:

Manual, automatic & CNC machines

- Manual machines enable simple fabrication but offer less precision and consistency than automated options.

- Automatic machines utilize pneumatic or hydraulic actuation to automate fabrication processes but still require manual loading/unloading.

- CNC machines integrate computer numeric control, allowing for precise, automated, high-volume busbar machining customizable via software.

All-In-One & Standalone Machines

- All-in-one machines combine multiple machining capabilities (cutting, bending, punching, etc.) into one device. They maximize efficiency but are generally only viable for high-production operations.

- Standalone machines focus on a single process. They provide flexibility for lower volume production or custom work where multiple processes are unnecessary.

Fixed vs. Adjustable Processing

Another classification considers whether the machine’s processing capabilities are:

- Fixed – Machines with fixed tooling/capabilities, suitable for high-volume production of identical busbar components.

- Adjustable – Machines where process variables like bend angles, hole sizes, and lengths can be altered as needed without changing tooling. Added flexibility suits low to medium production.

There are also various machine orientations and sizes to suit different production scales and workshop layouts.

Busbar Machine Applications

Busbar machines enable the automated, high-volume production of busbars ready for installation into electrical infrastructure projects or equipment including:

- Power distribution networks

- Substations

- Transformers

- Switchgear and motor control centers

- UPS and backup power systems

- Electric vehicle powertrains

- Wind turbines, solar inverters, and other renewable energy systems

- Industrial equipment and machinery

- Commercial buildings

- Data centers

- Ships

- Rail systems

- And more

Essentially, any application where electricity flows through busbars requires them to be fabricated to suit specific connection layouts, dimensions, ratings, and other custom considerations.

The Takeaway

A busbar machine is an essential processing device that enables the automated fabrication of busbars to suit various applications in electrical power infrastructure and equipment.

These rugged metalworking machines transform raw busbar stock into finished components with holes, bends, identification marks, and cuts meeting exact electrical design specifications.

Understanding busbar machine capabilities and processes provides key insight into a fundamental yet easily overlooked aspect of managing and distributing electrical power.