Leading Busbar Bending Machine and Copper Cutting Machine Manufacturer

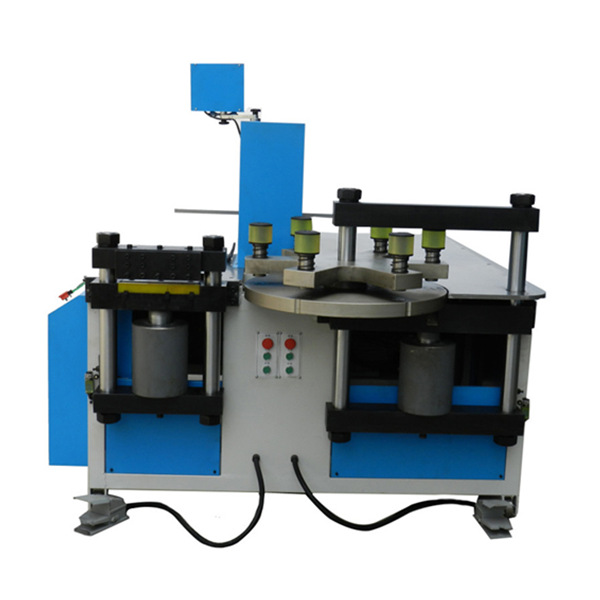

As a leading manufacturer, we present a comprehensive range of products, including busbar bending machines, CNC busbar machines, busbar punching machines, and busbar processing machines. Engineered for efficiency and precision, our products redefine the standards in the B2B market. Explore our catalog and experience unparalleled performance and reliability.

Busbar Machine Manufacturer

BM Machinery Equipment Company is a joint-stock enterprise specializing in the development, production, and sale of a series of busbar machine equipment. Our primary focus includes CNC busbar machines, busbar bending machines, busbar punching machines, busbar processing machines, and hydraulic busbar bending machines, among other products.

Since its inception, BM Busbar Machine Trading Company has evolved into a professional domestic base for bus processing equipment production. This has been made possible due to our mission of “commitment to human science and technology, driven by current technology”, the guarantee of advanced production methods, and stringent management. We pride ourselves on offering excellent quality, stable performance, and a diverse range of products.

Types of Busbar Machine We Made

Our Busbar Machine Products

- CNC Busbar Bending Machine

- Copper Busbar Bending Machine

- Copper Busbar Cutting Machine

- Busbar Punching Machine

- Busbar Machine Dies

30 tons cnc copper busbar bending cutting and punching machine

50 tons copper hydraulic busbar bending cutting and punching machine

30 tons cnc copper busbar bending cutting and punching machine

50 tons copper hydraulic busbar bending cutting and punching machine

DHY-200 portable manual hydraulic busbar bending machine

CB-150D portable manual hydraulic copper and iron bending machine tools

30 tons cnc copper busbar bending cutting and punching machine

50 tons copper hydraulic busbar bending cutting and punching machine

CWC-200 hydraulic manual portable copper steel busbar cutting machine tools

CWC-150 portable manual copper busbar cutting machine

DHY-200 portable manual hydraulic busbar bending machine

30 tons cnc copper busbar bending cutting and punching machine

50 tons copper hydraulic busbar bending cutting and punching machine

CH-80 iron and steel hydraulic busbar punching machine

CH-60 portable copper and aluminum busbar punching machine

DHY-200 portable manual hydraulic busbar bending machine

Busbar Machine Applications

Electrical and Electronics Industry

Busbar apparatuses play a pivotal role in constructing electrical switchgear, transformers, and other essentials demanding accurate and effective busbar processing.

High and Low Voltage Switchgear and Transformer Manufacturing

Busbar machinery is primarily deployed in the production of high and low voltage switchgear along with transformers.

Automotive Manufacturing

Within the automobile industry, busbar apparatuses are employed in the creation of Battery Management Systems (BMS), and Electric Vehicle (EV) powertrain components.

Other Industries

The adaptability of busbar machines extends to domains like naval architecture, office automation devices, elevator producing, chassis, and cabinet manufacturing, and beyond.

Why Choose Us as Busbar Machine Supplier

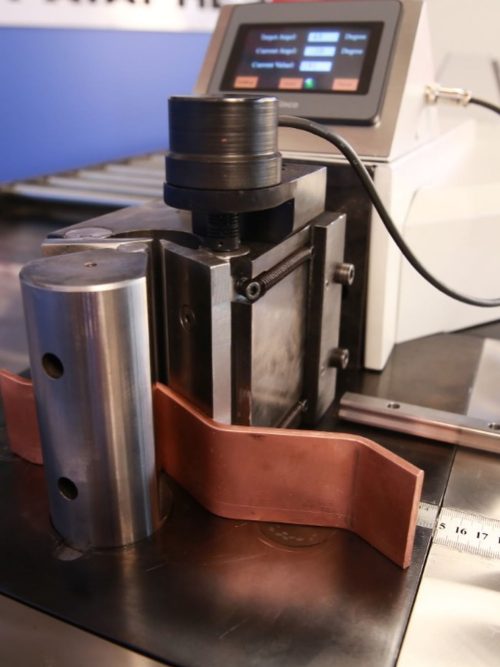

High Precision & Accuracy

Our busbar machinery has been designed to execute functions such as cutting, punching, and bending with high precision, ensuring the final busbars perfectly match their specifications.

Increased Productivity

Our machinery is usually multifunctional and capable of effectively carrying out various manufacturing tasks. This multifaceted nature leads to enhanced productivity, speeding up the production process.

Automation & Reduced Labor Costs

Our busbar machines possess powerful automation capabilities, decreasing manual input dependency for tedious and time-consuming tasks.

Reduced Waste

The precision in our cutting and processing protocols mitigates the waste of materials, leading to cost-effectiveness and promoting a greener manufacturing procedure.

Quality and Reliability

Our machines hold certifications from ISO & CE, proving they adhere to globally recognized standards of quality and dependability. Our clientele from diverse regions, such as North America, Europe, and Asia, acknowledge and esteem this.

Low Maintenance Costs

Hydraulic busbar bending machines, a notable component of our product lineup, are renowned for their low-cost maintenance. The infrequency of necessary servicing equates to additional savings.

Flexibility & User-Friendly Design

Our CNC busbar machines are versatile and capable of processing varying shapes and sizes of busbars, making them adaptable for many applications. Their design also encompasses user-friendly interfaces for efficient operation.

After-Sales Service and Support

We take our clients' feedback seriously, leveraging it to refine the technical specifications of our machinery. Our post-sales service is directed towards ensuring customer gratification and delivering support whenever required.

Our Busbar MachineFactory

After-Sales Support of Our Busbar Machines

Prolific Customer Care

We uphold an unwavering commitment to offer comprehensive support post-purchase. Our customer care team always addresses your inquiries and concerns, ensuring a seamless experience with our busbar machines.

Technical Helpdesk

Our technical support desk is backed by a team of experts well-versed in the workings of our machinery. They are proficient in troubleshooting and assisting with operational queries to maintain the efficiency of your busbar machines.

Regular Maintenance Services

We provide scheduled maintenance services to ensure your busbar machines function optimally. Our dedicated crew keeps your machines running smoothly, mitigating the potential for unplanned downtime.

Prompt Parts Delivery

Understanding the importance of timely part replacements, we maintain an extensive inventory of genuine machine parts. We can quickly dispatch these parts, minimizing disruption in your production line. Thus, our after-sales support significantly enhances your machine’s lifespan and productivity.

Busbar Machine FAQs

A busbar machine can perform various tasks, including cutting, punching, and bending busbars. This multitasking ability makes it an indispensable tool in electrical manufacturing processes.

Yes, our busbar machines are designed with automation capabilities. They significantly reduce the need for manual labor by performing time-consuming and repetitive tasks automatically. This feature enhances productivity and operational efficiency.

Our busbar machines adhere strictly to international quality and dependability standards. They are approved by ISO & CE certifications, a testament to their superior quality.

No, our hydraulic busbar bending machines are renowned for their minimal maintenance requirements. This feature reduces your servicing costs and leads to additional savings in the long run.

Our CNC busbar machines offer versatility in terms of processing. They can handle different shapes and sizes of busbars, making them adaptable to various applications.

We greatly emphasize customer satisfaction. Our after-sales service includes prolific customer care, a dedicated technical support desk for troubleshooting, regular maintenance services, and prompt parts delivery. Our team is always ready to assist with any concerns or queries you may have after your purchase.